PCR Polyolefin Shrink Film: Sustainable Packaging Made Easy

Feb 25,2026How Low Temperature Cross-Linked Film Keeps Products Safe and Fresh

Feb 18,2026Why Low Temperature Cross-Linked Film is a Game Changer for Packaging

Feb 11,2026Unlocking Packaging Efficiency: A Deep Dive into Polyolefin (POF) Shrink Film Applications

Feb 03,2026Why POF Shrink Film Is Becoming the Go-To Packaging Solution for Modern Manufacturers

Jan 27,2026You asked about the polymers used to create Cross-Linked Shrink Film. The primary material in today's high-performance shrink packaging is polyolefin (POF), which includes variations like polypropylene and polyethylene. The older, less-common material is Polyvinyl Chloride (PVC). Understanding the differences is key to selecting the right packaging solution.

The cross-linking process is most effectively and commonly applied to polyolefin (POF) films. While PVC was historically popular, it is rarely cross-linked and has largely been superseded by POF due to environmental, safety, and performance concerns.

Here is a comparison of the two main types of shrink film polymers:

| Feature | Cross-Linked Polyolefin (POF) | Polyvinyl Chloride (PVC) |

| Material Composition | Non-toxic blend of polypropylene (PP) and polyethylene (PE). | Contains chlorine and plasticizers (often phthalates). |

| Cross-Linking | Common and highly beneficial. Provides superior strength and stability. | Not typically cross-linked; process is difficult and less common. |

| Clarity & Appearance | Excellent clarity, high gloss, and soft feel. | Good clarity, high gloss, but can yellow/become brittle over time. |

| Strength & Durability | Superior tear and puncture resistance. Ideal for heavy or irregular products. | Good strength, but more prone to brittleness and tears in cold weather. |

| Sealing Fumes & Odor | Minimal to no smoke or odor when heat-sealed. | Releases strong, harmful fumes (hydrogen chloride gas) when heated. |

| Environmental Impact | Recyclable (where accepted), often FDA approved for direct food contact. | Contains toxins; not easily recyclable; banned in some countries/states. |

| Cold Resistance | Excellent; remains flexible and stable in freezer conditions. | Poor; can become stiff and crack easily in cold temperatures. |

The molecular cross-linking only magnifies the inherent advantages of Polyolefin. The resulting film is a highly versatile and safe packaging material that addresses the major drawbacks of PVC:

Safety and Environment: POF is chlorine-free, making it non-toxic and safer for both the packaged goods (especially food) and the operating staff (no hazardous fumes).

Operational Efficiency: The heat stability provided by the cross-links drastically reduces film breakage and residue buildup on sealing equipment, leading to higher throughput and lower maintenance costs.

Versatility: Its superior cold resistance makes it suitable for products that need to be refrigerated or frozen, maintaining its clarity and strength throughout the supply chain.

In summary, when specifying a Cross-Linked Shrink Film, you are almost certainly selecting a polyolefin-based material, leveraging modern chemical engineering to achieve a package that is stronger, clearer, and operationally safer than its PVC predecessor.

Would you like a more detailed breakdown of the irradiation process used to create the cross-links in the film?

That's an excellent question, as the irradiation process is the "secret sauce" that transforms standard polyolefin film into high-performance Cross-Linked Shrink Film.

The most common and efficient method used in continuous film production is Electron-Beam (E-Beam) Irradiation. This is a physical process that fundamentally changes the polymer's molecular structurewithoutthe need for high heat or chemical additives.

The process involves running the extruded polyolefin film under a high-energy electron accelerator.

Preparation: The polyolefin polymer is first extruded into a film. It is a thermoplastic material, meaning its long, linear molecular chains soften and flow when heated (like butter).

Irradiation: The film is conveyed rapidly beneath an electron-beam accelerator. The accelerator generates a controlled stream of high-energy electrons.

Molecular Change: As the electrons penetrate the polymer, they collide with the molecular chains. This collision knocks off certain atoms (typically hydrogen atoms), creating highly reactive sites called free radicals along the polymer backbone. *

Cross-Linking: The free radicals on neighboring polymer chains immediately seek to stabilize themselves by forming new, permanent chemical bonds—these are the cross-links. This creates a complex, three-dimensional network structure within the polymer, much like a microscopic mesh or net.

Thermoset Conversion: This new network structure converts the material from athermoplasticinto a thermoset material. It now has a molecular "memory" or shape memory.

The newly formed cross-linked network is what provides the dramatic improvements in the finished Cross-Linked Shrink Film:

Heat Stability: The network prevents the molecular chains from simply flowing apart when heated. The film will shrink, but it will not melt, char, or stick to the sealing wire, which is a major issue with non-cross-linked films.

Elastic Memory: When the film is initially processed, it is deliberately stretched. The cross-links lock the polymer in this stretched, "expanded" state. When heat is applied later (in the shrink tunnel), the polymer attempts to revert to its original, un-stretched size, resulting in a tight, clean shrink.

Enhanced Mechanical Strength: The three-dimensional network makes it exponentially harder to pull the chains apart, giving the film its superior puncture and tear resistance.

Electron-beam cross-linking is favored over chemical methods because it is a clean, fast, and highly controlled process that leaves no chemical residues and ensures uniform cross-link density throughout the film.

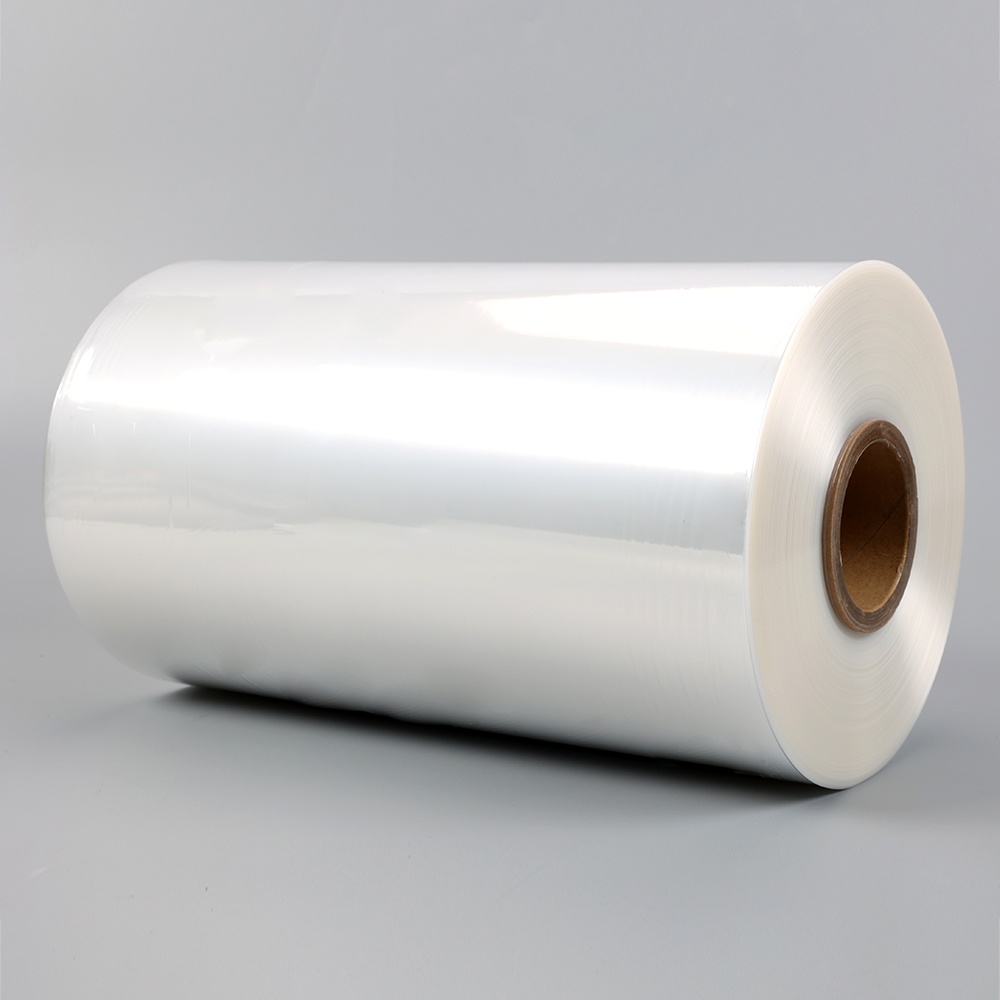

Polyolefin Shrink Film Roll: Versatility and Performance in Modern Packaging

How Does POF Film Typically Perform at Cold Temperatures Compared to PVC Shrink Film?

Mobile site

alibaba

Copyright © 2023 Zhejiang Zhongcheng Packing Material Co., Ltd. All Rights Reserved. Privacy Polyolefin Shrink Film Manufacturers