PCR Polyolefin Shrink Film: Sustainable Packaging Made Easy

Feb 25,2026How Low Temperature Cross-Linked Film Keeps Products Safe and Fresh

Feb 18,2026Why Low Temperature Cross-Linked Film is a Game Changer for Packaging

Feb 11,2026Unlocking Packaging Efficiency: A Deep Dive into Polyolefin (POF) Shrink Film Applications

Feb 03,2026Why POF Shrink Film Is Becoming the Go-To Packaging Solution for Modern Manufacturers

Jan 27,2026Shrink film plays a crucial role in modern packaging, providing protection, tamper-evidence, and an appealing presentation for a vast array of products. Among the most common types are polyolefin (POF) and polyvinyl chloride (PVC) shrink films, each with distinct properties and applications. Understanding their differences is key to selecting the optimal packaging solution.

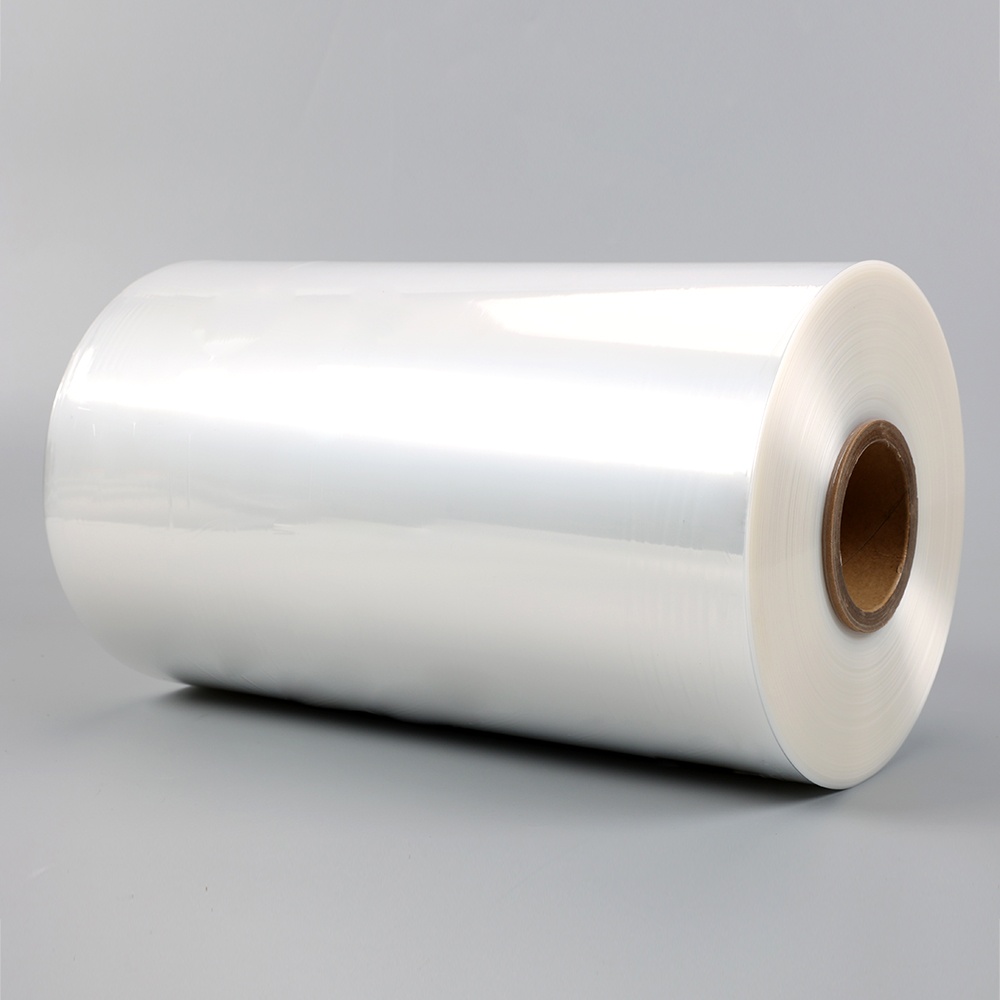

Polyolefin shrink film has emerged as the preferred choice for many packaging applications due to its superior performance and environmental considerations. It's a versatile, multi-layered film often made from a blend of polyethylene (PE) and polypropylene (PP).

Exceptional Clarity and Gloss: POF offers superior optical transparency, providing a crystal-clear, glossy finish that enhances product visibility and shelf appeal.

Durability and Puncture Resistance: This film boasts excellent tensile strength and is highly resistant to punctures and tears, making it ideal for protecting irregularly shaped or heavy items during transit and handling. Cross-linked POF films offer even greater strength and durability.

Food Safe and Non-Toxic: POF is non-toxic and FDA-approved for direct food contact, making it a safe and popular choice for packaging food products, including baked goods, produce, and frozen items.

Odorless Sealing: When heated, POF films produce no significant odors or fumes, which is beneficial for both the packaging environment and the products themselves, especially food items.

Strong, Clean Seals: POF creates strong, aesthetically pleasing seals that hold up well over time and across varying temperatures.

Versatility: It performs well on both manual and automated packaging equipment and can be used for single items or bundling multiple products.

Temperature Stability: POF maintains its integrity across a wide range of temperatures, meaning it won't become brittle in cold conditions or soft in hot environments.

Environmental Friendliness: POF is generally considered more environmentally friendly than PVC. It's recyclable and does not contain chlorine, meaning it doesn't release harmful hydrogen chloride gas during sealing or disposal.

Food packaging (fresh produce, baked goods, frozen foods, confectionery)

Cosmetics and personal care products

Electronics and software

Toys and games

Printed materials (books, magazines)

Pharmaceuticals

Sporting goods

Retail consumer goods where presentation is critical

For many years, PVC shrink film was the most commonly used shrink wrap. Made from polyvinyl chloride, it offers distinct advantages, particularly in terms of cost.

Cost-Effectiveness: PVC is typically less expensive than POF, making it an attractive option for businesses with budget constraints.

Good Shrinkage at Lower Temperatures: PVC shrinks effectively at lower temperatures, which can be advantageous for heat-sensitive products.

High Shrink Force: It exerts a high shrinkage force, allowing it to tightly conform to the shape of products.

Clarity and Sheen: While not as brilliant as POF, PVC offers good clarity and a decent sheen for product display.

Durability: PVC is resistant to tearing and punctures, providing good protection for packaged goods.

Ease of Use: It is generally easy to control during the shrinking process and can be scuff-resistant.

CDs and DVDs

Software packaging

Gift baskets

Small canisters and boxes (non-edible items)

Some industrial applications where cost is a primary concern

Certain types of printed materials

|

Feature |

Polyolefin (POF) Shrink Film |

Polyvinyl Chloride (PVC) Shrink Film |

|

Composition |

Made from polyolefins (e.g., polyethylene, polypropylene) |

Made from polyvinyl chloride (PVC) |

|

Clarity & Gloss |

Excellent, highly transparent with a glossy finish |

Good, but can appear slightly hazy compared to POF |

|

Durability |

Superior puncture and tear resistance, high tensile strength |

Good puncture and tear resistance |

|

Food Safety |

FDA approved for direct food contact, non-toxic |

Not recommended for direct food contact; often for secondary packaging |

|

Odor/Fumes |

Odorless during sealing; no harmful fumes |

Can emit a slight odor and hydrogen chloride gas during sealing |

|

Seal Quality |

Strong, clean, durable seals |

Strong seals, but can be brittle in cold temperatures |

|

Temperature Range |

Stable across a wide range of temperatures |

Can harden in cold and soften in heat, affecting seal integrity |

|

Environmental Impact |

Recyclable, chlorine-free, more environmentally friendly |

Less environmentally friendly due to chlorine content and disposal concerns |

|

Cost |

Generally higher upfront cost |

More cost-effective |

|

Machine Compatibility |

Excellent for high-speed automatic machines; less residue build-up |

Compatible with various machines, but can leave carbon deposits |

|

Feel |

Softer and more elastic |

Harder after heat is applied, less elastic |

The choice between polyolefin and PVC shrink film depends heavily on the specific application, product requirements, and environmental considerations.

Polyolefin (POF) is the modern, versatile, and high-performance choice, particularly favored for products requiring excellent clarity, durability, and direct food contact. Its environmental benefits and superior sealing characteristics make it a robust solution for a wide range of consumer and industrial goods.

Polyvinyl Chloride (PVC), while more traditional and less expensive, remains a viable option for non-food items where budget is a primary driver and the slight odor or environmental impact is less critical. Its ability to shrink at lower temperatures can also be an advantage for certain delicate products.

Ultimately, careful consideration of factors like product type, desired appearance, protection needs, production efficiency, and environmental responsibility will guide the decision toward the most suitable shrink film for your packaging needs.

Mobile site

alibaba

Copyright © 2023 Zhejiang Zhongcheng Packing Material Co., Ltd. All Rights Reserved. Privacy Polyolefin Shrink Film Manufacturers