Why POF Shrink Film Is Becoming the Go-To Packaging Solution for Modern Manufacturers

Jan 27,2026POF Film Explained: Performance Advantages, Application Scenarios, and Buying Considerations for Modern Packaging

Jan 21,2026Is Your Production Line Ready for High-speed Packaging Polyolefin Shrink Film?

Jan 14,2026Why is Shading Cross-Linked Shrink Film Revolutionizing the Protection of Light-Sensitive Products?

Jan 06,2026The Ultimate Guide to Cross-Linked Shrink Film: Why It’s the Gold Standard for Modern Packaging

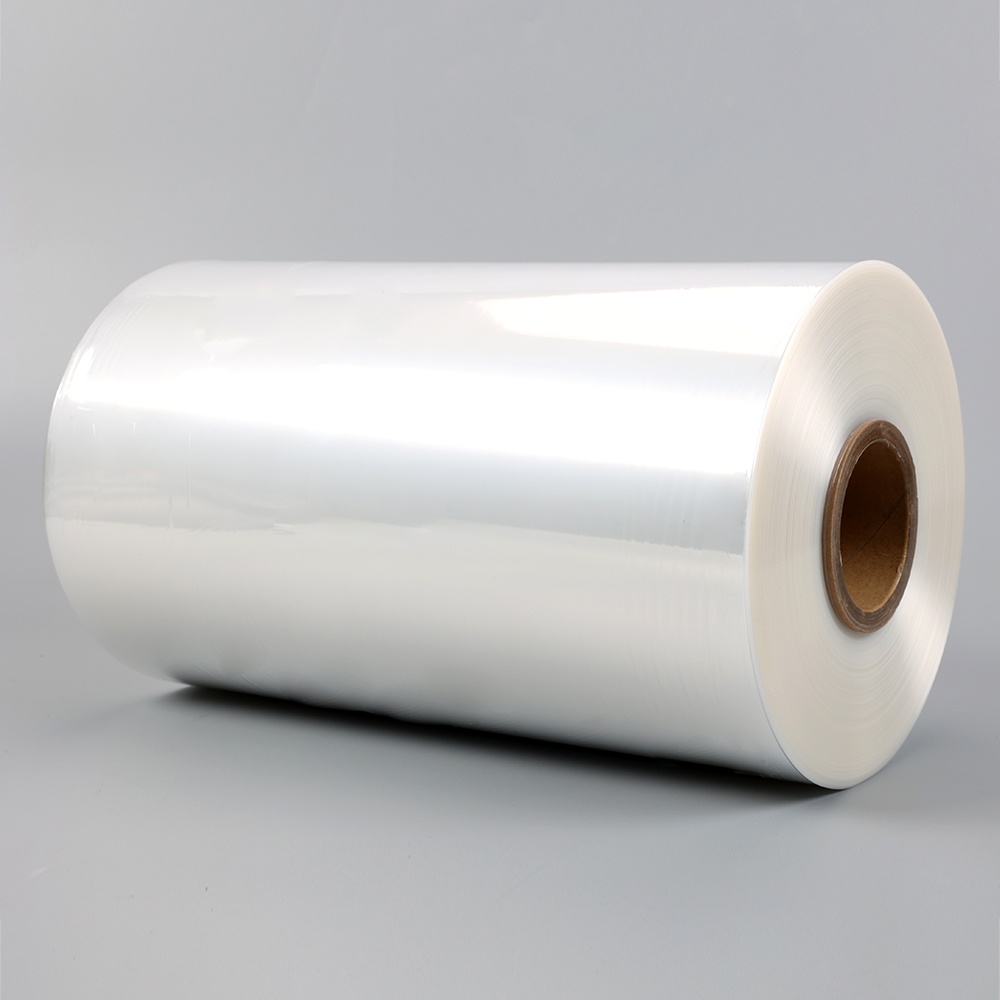

Jan 04,2026POF film, short for Polyolefin Shrink Film, is a high-performance plastic packaging material widely used for retail, industrial, and food packaging. It is produced through co-extrusion technology using polyethylene and polypropylene resins, resulting in a film that balances strength, flexibility, and clarity. Unlike traditional shrink films, POF film offers stable shrink behavior across a wide temperature range, making it suitable for both manual and automated packaging lines.

The popularity of POF film comes from its clean appearance, food-grade safety, and adaptability to different product shapes. As brands focus more on presentation, logistics efficiency, and sustainability, POF film has become the preferred choice over PVC and conventional PE shrink films.

POF film delivers a combination of mechanical strength and aesthetic quality that directly impacts packaging efficiency and product protection. Its balanced shrink force ensures tight wrapping without product deformation, even for lightweight or irregular items.

POF film is widely applied across industries that require clean packaging, high output, and reliable protection. Its adaptability allows it to work with L-bar sealers, side sealers, and fully automatic shrink wrapping machines.

Typical applications include multi-pack beverages, cosmetics, printed materials, stationery, toys, electronics accessories, and pharmaceutical boxes. In food packaging, POF film is commonly used for bakery items, frozen foods, and fresh produce trays due to its compliance with food contact standards.

Selecting the correct POF film thickness is critical for balancing material cost and packaging performance. Thinner films offer material savings and faster shrink speeds, while thicker films provide enhanced durability for heavier products.

| Thickness (Micron) | Recommended Application |

| 12–15 | Lightweight products, printed materials, cosmetics |

| 19–25 | Food trays, boxed goods, daily consumer products |

| 30+ | Heavy items, bundled products, industrial packaging |

When compared with PVC and PE shrink films, POF film offers a more balanced solution for modern packaging demands. PVC film provides strong shrink force but releases unpleasant odors and has environmental concerns. PE shrink film is durable but lacks clarity and tight wrapping performance for small items.

POF film stands out by combining clarity, environmental friendliness, and versatile application, making it the preferred option for export-oriented and brand-focused packaging operations.

High-quality POF film should demonstrate uniform thickness, stable shrink ratios, and smooth sealing performance. Poor-quality film often results in inconsistent shrinkage, weak seals, and higher rejection rates during packaging.

Different packaging machines require specific film formulations. Ensuring compatibility with your sealing system and shrink tunnel temperature range helps maximize efficiency and reduce downtime.

While premium POF film may have a higher unit price, its superior shrink performance, reduced waste, and lower breakage rates often result in lower overall packaging costs in long-term production.

Why POF Shrink Film Is Becoming the Go-To Packaging Solution for Modern Manufacturers

Is Your Production Line Ready for High-speed Packaging Polyolefin Shrink Film?

Mobile site

alibaba

Copyright © 2023 Zhejiang Zhongcheng Packing Material Co., Ltd. All Rights Reserved. Privacy Polyolefin Shrink Film Manufacturers